What is ASTM A193 bolts ?

ASTM A193 is a bonding consumable standard covering alloy and stainless steel bolts and threaded rods for use with flanges, valves, pressure vessels and fittings for high temperature and high pressure service. Alpha Fastener Company is providing ASTM A193 bolts of which the most popular are ASTM A193 B7, B7M bolts with blue or green PTFE coating along with nuts ASTM A194 2H.

Application

Tiêu chuẩn này thông thường được sử dụng trong các lĩnh vực sau:

- Bolts ASTM A193 B7/2H, B8 Used on flanges connecting pipes in water supply, petrochemical, processing industry

- Bolts B7, B16 in oil and gas, aerospace, power generation, oil refining, chemicals…

- B8 and B8M used as a stainless steel valve, controlling the movement of liquid through the pipeline. When the temperature is high, useB16

- Also widely used in the manufacture of boilers containing water or heated liquids, heat exchangers are used to transfer heat between one or more liquids (or gases) without mixing with each other.

Shape

A193 bolts are most commonly specified, manufactured and supplied as hex bolts or threaded rods. However, the specification does not restrict A193 bolts to be produced only in this shape. Wide range of bent bolts, rods with threads at one or both ends, and bolts with heads other than hexagonal Also machined to ASTM A193 specification. All bolts and threaded rods must be chamfered (pointed). .

Mechanical – chemical – washer – nut included

Table of mechanical properties and production materials

| Grade | Size (inch) |

Tensile strength min (ksi) |

Yield strength min (ksi) |

Elongation (%) |

RA min (%) |

HBW | HRC | Crafting materials |

|---|---|---|---|---|---|---|---|---|

| B7 | 2½ or less | 125 | 105 | 16 | 50 | 321 max | 35 max | Chromium and molybdenum alloy steel (AISI 4140/4142) heat-treated and tempered |

| 2⅝ – 4 | 115 | 95 | ||||||

| 4⅛ – 8 | 100 | 75 | ||||||

| B7M | 4 or less | 100 | 80 | 18 | 50 | 235 max | – | |

| over 4 – 7 | 100 | 75 | ||||||

| B8 type 1 |

All | 75 | 30 | 30 | 50 | 223 max | 96 max | AISI 304 stainless steel is treated with a carbide solution. Type 2 is hardened for increased strength and stretchability |

| B8 tybe 2 (B8SH) |

¾ or less | 125 | 100 | 12 | 35 | 321 max | 35 max | |

| ⅞ – 1 | 115 | 80 | 15 | 35 | ||||

| 1⅛ – 1¼ | 105 | 65 | 20 | 35 | ||||

| 1⅜ – 1½ | 100 | 50 | 28 | 45 | ||||

| B8M type 1 |

All | 75 | 30 | 30 | 50 | 223 max | 96 max | AISI 316 stainless steel (with molybdenum) is carbide-treated. Type 2 has increased surface strength and reduced sensitivity to running water |

| B8M type 2 (B8MSH) |

¾ or less | 110 | 95 | 15 | 45 | 321 max | 35 max | |

| ⅞ – 1 | 100 | 80 | 20 | 45 | ||||

| 1⅛ – 1¼ | 95 | 65 | 25 | 45 | ||||

| 1⅜ – 1½ | 90 | 50 | 30 | 45 | ||||

| B16 | 2½ or less | 125 | 105 | 18 | 50 | 321 max | 35 max | Heat-treated and tempered chromium-molybdenum-vanadium alloy steel |

| 2⅝ – 4 | 110 | 95 | 17 | 45 | ||||

| 4⅛ – 8 | 100 | 85 | 16 | 45 |

Mechanical table and production materials

| Ingredient | B7, B7M (AISI 4140) | B8 (AISI 304) | B8M (AISI 316) | B16 (AISI 316) |

|---|---|---|---|---|

| Carbon | 0.37 – 0.49 | 0.08 | 0.08 | 0.36 – 0.47 |

| Mangan, max | 0.65 – 1.1 | 2 | 2 | 0.45 – 0.7 |

| Phosphorus , max |

0.035 | 0.045 | 0.045 | 0.035 |

| Sulfur , max |

0.04 | 0.03 | 0.03 | 0.04 |

| Silicon | 0.15 – 0.35 | 1 | 1 | 0.15 – 0.35 |

| Crom | 0.75 – 1.2 | 18 – 20 | 16 – 18 | 0.8 – 1.15 |

| Molypden | 0.15 – 0.25 | – | 2 – 3 | 0.5 – 0.65 |

| Niken | – | 8 – 11 | 10 – 14 | – |

| Vanadi | – | – | – | 0.25 – 0.35 |

| Aluminum , max |

– | – | – | 0.015 |

Bolts – Nuts – Washer included (recommended)

| Bolts Grade | Nuts | Washer |

|---|---|---|

| B7 | A194 grade 2H | F436 |

| B7M | A194 grade 2HM | F436 |

| B8 type 1 | A194 grade 8 | SUS 304 |

| B8M type 1 | A194 grade 8M | SUS 316 |

| B8 type 2 | A194 grade 8 | SUS 304 |

| B8M type 2 | A194 grade 8M | SUS 316 |

| B16 | A194 grade 4, 7 or 16 | F436 |

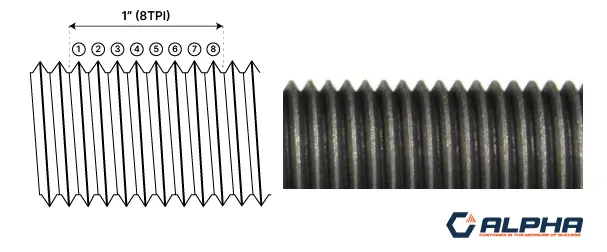

Thread pitch

UNC is the most popular thread pitch standard in the United States. Thread pitch is uniform designs with 60° thread angles and several diameter-step combinations. 8UN thread pitch is a UNC pitch variation, the “8” in 8UN means that on a given nominal diameter 8UN thread pitch is always 8 TPI (number of threads per inch), for all lines lace glasses .

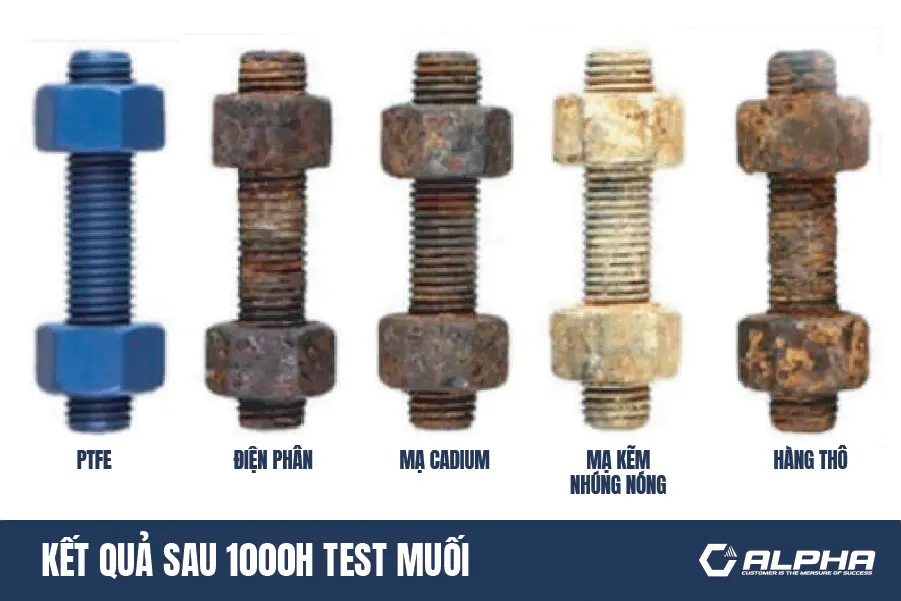

Platings

Some fasteners manufactured to ASTM A193 may be zinc coated according to F2329 (hot dip galvanizing), B695 (mechanical galvanizing) or F1941 (galvanizing). Especially Teflon, Xylan and PTFE coatings are commonly used with A193 . bolts .

Standards and advantages of PTFE coating

Standards

- Teflon, Xylan, PTFE (Polytetrafluoroethene), commonly known as “non-stick coating” or easy-to-clean “material”, is a type that uses all the hydrogen atoms in a synthetic polymer, synthetic resin material. fluorinated. This material is resistant to acids and alkalis, resistant to the properties of organic solvents, and almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, low coefficient of friction, so it can make lubricating and also an ideal easy-to-clean coating of pipe liners. .

- The method of coating application must ensure that damage through stagnation is slow (hydrogen is avoided). This is especially important in the case of high-strength steels of grades B, C and D having a tensile strength of >1000 N/mm². Application must be made in accordance with ASTM B841 and related standards. Surface must be treated with chromate conversion treatment also according to ASTM B841.

- The coating must be able to pass the adhesion test specified in ASTM B571 . .

- The PTFE top coat for bolted components shall be Xylan 1070® (or) equivalent. The selected material must contain polytetrafluorethylene along with polyamide/polyimide esters and color pigments and be the base cure. The selected material must withstand temperatures from -50°C to +200°C.

- The dry film thickness of the PTFE coating on the screw wall should not be less than 25 microns and not more than 40 microns. Coating shall be applied in accordance with ASTM D823. The application of the coating must be applied with a minimum of two (or 3) coats .

- The fluorocarbon (PTFE) coating system is to be tested in an ASTM B117 salt mist chamber for 3000 hours.

- A corrosion test for PTFE coating on Zn-Ni plated stud-studs shall be performed in accordance with ASTM B117 (salt spray test) for a minimum period of 3000 hours. .

Advantages

- Anti-rust in alkaline, salt, sea water.

- Non-stick to nearly all materials with teflon coating .

- Heat-resistant, teflon coating has excellent heat resistance and low heat resistance properties. High temperature stability resistance to 300 , medium short time between 240℃ ~ 240℃ can be used continuously, has considerable thermal stability; it can work under freezing temperature and is not brittle, does not melt at high temperature .

- Slip: teflon coating has a lower coefficient of friction. Load when the coefficient of sliding friction changes, but the number is only between 0.05 and 0.15.

- Wet resistance: non-stick teflon surface coating of water and oil, production operations are also not easy to touch solution, such as with a small amount of dirt, easy to wipe can be removed. The time is short, which can save time and improve work efficiency.

- Wear resistance: under high load, has excellent wear resistance. For certain loads, there are dual advantages of wear resistance and adhesion.

- Corrosion resistance: ptfe is almost unaffected by drugs, can withstand in addition to molten alkali metal, medium fluoride and higher than 300 ℃ all strong acids sodium hydroxide (including hydro regia), strong Strong oxidizer, reductant, and organic solvents, can protect parts from chemical corrosion in any form. .

Size

At Alpha, we supply ASTM A193 bolts in both inch and metric systems. With a variety of sizes, to meet all customer needs .

Seal the product

All products manufactured at Alpha Fastener are stamped with the Logo and grade of durability (e.g. A193 B7) at the hexagon end. Allowing to omit stamping on products of very small diameter

Production speed

Our production plant is equipped with modern equipment, helping to achieve high output in a short time along with stock of popular sizes. Bring the best shopping experience to customers.